Śluza sanitarna

Fully automated spray disinfection booths.

The COVID-19 pandemic has permanently changed many aspects of our social behaviour and the way we move around in public area. It triggered the need to implement many safety procedures and a completely new approach to sanitary regime.

At present, we are faced with the challenge of functioning in the new sanitary regime. In response to the new reality, we have developed Sanitary Gate, a specialized, fully-automatic decontamination sluice, equipped with spray disinfection mechanism.

Sanitary Gates guarantee the safest disinfection by means of fully-automatic operation, which is triggered after crossing the sensor barrier. Assembled in front of public utility buildings or in other areas with heavy human traffic, the sanitary gate allows for highly efficient, safe and effective disinfection. Our offer includes two gate models and a wide range of accessory equipment, selected to meet the customer’s requirements.

Specyfikacja techniczna

KABINA ŚLUZY | ||

|---|---|---|

Wymiary | 250 cm X 160cm X 210cm (wysokość x szerokość x długość) | |

Szerokość z hydroforem | 200cm | |

Konstrukcja | Ceowniki stalowe, spawane, lakierowane proszkowo | |

Obudowa | poliwęglan komorowy mleczny gr. 10mm | |

Podest wymiary | 160cm X 100cm (podest wyposażony w odwodnienie) | |

MODUŁ DO DEZYNFEKCJI | ||

|---|---|---|

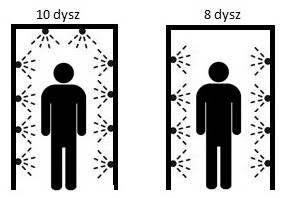

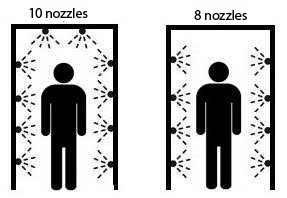

Liczba dezynfekujących dysz zraszających | 10 lub 8sztuk | |

Średnica dysz zraszających | 0,15mm lub 0,08mm | |

Rozmieszczenie dysz zraszających na bocznych ścianach śluzy |  | |

Ciśnienie robocze dysz zraszających | max 5 barów | |

Sposób uruchamiania | automatyczny po przekroczeniu bariery fotokomórkowej | |

Regulacja czasu zamgławiania | od 3 do 15 sekund | |

Kontrolne sygnały świetlne | zielone – śluza gotowa do pracy, czerwone – śluza w trakcie pracy lub brak płynu dezynfekującego | |

ZBIORNIK NA PŁYN DEZYNFEKUJĄCY | ||

|---|---|---|

Pojemność | 26 litrów | |

Materiał | stal nierdzewna | |

Wyposażenie | czujnik niskiego poziomu płynu | |

OPCJE WYPOSAŻENIA | ||

|---|---|---|

Podest | pianka dezynfekująca obuwie lub krata pomostowa | |

Kurtyna z pasów PVC | ||

Wariant dwukierunkowy kabiny | daje możliwość wejścia w obręb śluzy z dwóch stron | |

Performance in detail:

The disinfection process is automatically activated upon crossing of the sensor barrier. The user stands on a special platform which can be additionally equipped with a sanitary mat used to disinfect footwear or a galvanized steel grid. The platform is equipped with mechanism removing the surplus liquid.

The disinfection process is automatically activated upon crossing of the sensor barrier. The user stands on a special platform which can be additionally equipped with a sanitary mat used to disinfect footwear or a galvanized steel grid. The platform is equipped with mechanism removing the surplus liquid.

The nozzles activate automatically and the spraying time ranges from 3 to 15 seconds. Each gate is equipped with steering lights installed inside and outside the booth. Green light signals the readiness to work red light informs about the disinfection in progress. The end of disinfection is announced with a sound signal.

The gate is equipped with a low-level of disinfectant sensor. Red light and a sound signal inform about the necessity to add disinfecting liquid. The gate if also equipped with a low-level of disinfectant blockade, which protects the pumping mechanism from damage caused by “dry-operation”.

The main operational components of the gate include a 5 bar pumping mechanism and a 24-litre liquid tank. In addition, each gate is equipped with and additional 26-litre liquid tank.

The use of disinfectant depends on the number of nozzles and their diameter. It ranges from approx. 100 to 180ml per single disinfection. In order to reduce the use of disinfectant, selected nozzles may be sealed.

- Specification

- Pobierz model 3D